Minimizing Flaring – Pioneer seeks to minimize the flaring of gas in all our operations and continues to lead by example, having set an annual flaring intensity target of less than 1% of produced natural gas and a commitment to zero routine flaring by 2025. To achieve these ambitious targets, we have performed cross-departmental analyses, pilot testing and a thorough analysis of the root causes of conditions that can lead to flaring in our operations. Pioneer senior management is actively engaged in decision-making with the goal of keeping flaring to a minimum, adhering to our flaring intensity commitments.

Pioneer remotely monitors flaring through our supervisory control and data acquisition (SCADA) system, which triggers alerts for deviations in normal operating conditions. The system then directs a technician to quickly respond. Designated Pioneer operations personnel receive a daily log of actionable alerts and the response actions. Pioneer conducts monthly inspections and performs preventative maintenance to ensure the proper operation of flaring systems.

Pioneer requires wells to be connected to gas takeaway infrastructure before they are placed on production. We partner with third-party gathering, processing and pipeline operators to secure firm capacity and abate impacts from flow constraints. Together, we review production forecasts, system pressure models and project schedules, sharing responsibility to meet production demands and ensure emissions control. To further enhance our takeaway flexibility, Pioneer encourages our gas gatherers to interconnect gathering systems to provide incremental gas processing redundancy should parties have downtime. Pioneer also enters long-term commitments for firm transportation of oil, gas and natural gas liquids to markets outside the Permian Basin, including the U.S. Gulf Coast, U.S. West Coast, Mexico and international markets to mitigate the risk of oversupply in the Permian Basin.

Pioneer’s gas-gathering and processing agreements contain performance incentives and penalties, including requirements to maintain adequate system pressures to minimize emission events and contractual obligations to connect to new facilities prior to a well being placed on production.

Performance incentives include exclusive rights to gather and process production from high-volume areas as well as advanced notice of new producing areas to allow adequate time to build necessary infrastructure.

Penalties include the release of production to third parties if a gatherer cannot maintain adequate pressure rates to take all production at a battery or financial penalties if pressures exceed predetermined levels for a set period of time.

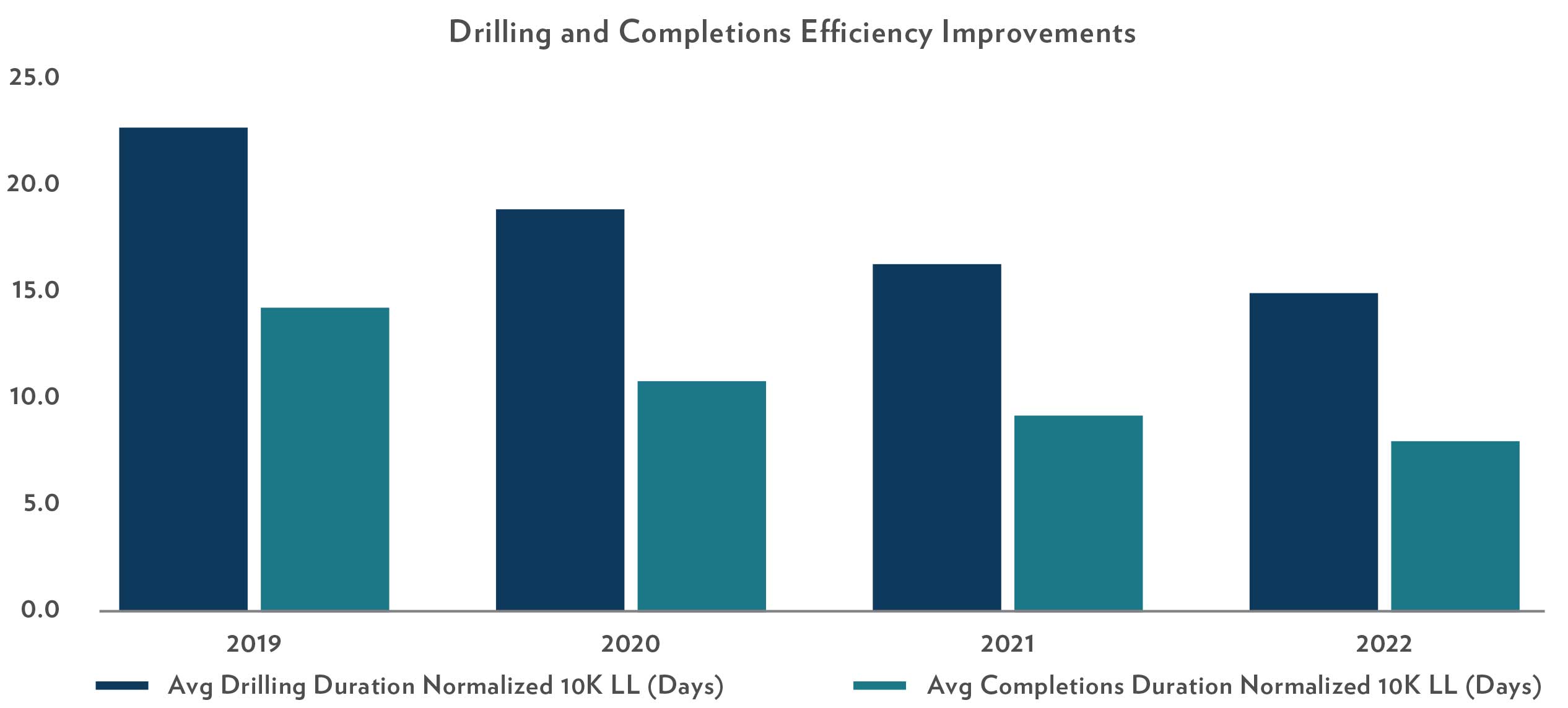

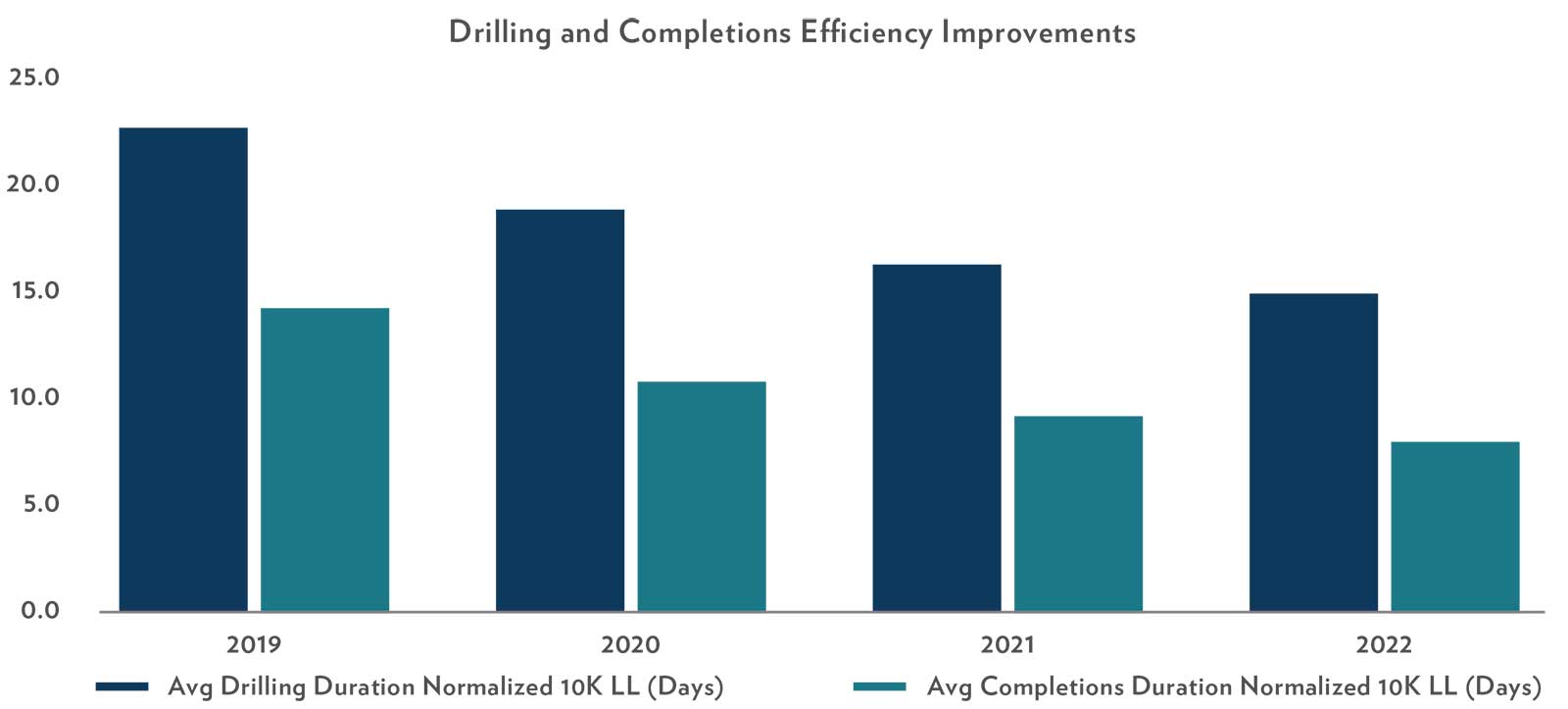

Reducing Diesel Fuel Combustion — Drilling and completing longer lateral wells more efficiently reduces the number of drilling rigs and pressure-pumping fleets which lowers the overall emissions required to place the same amount of lateral footage on production each year. Our drilling and completion operations continue to utilize technology and a culture of continuous improvement to increase operational efficiency. This, combined with a concentrated effort on supplying our fleets with more environmentally friendly power sources, has allowed us to drive significant reductions in GHG and non-GHG emissions. Also, by exploring new technologies, we are able to reduce emissions in the near-term as we plan for the transition to grid power as infrastructure allows in 2023 and beyond.

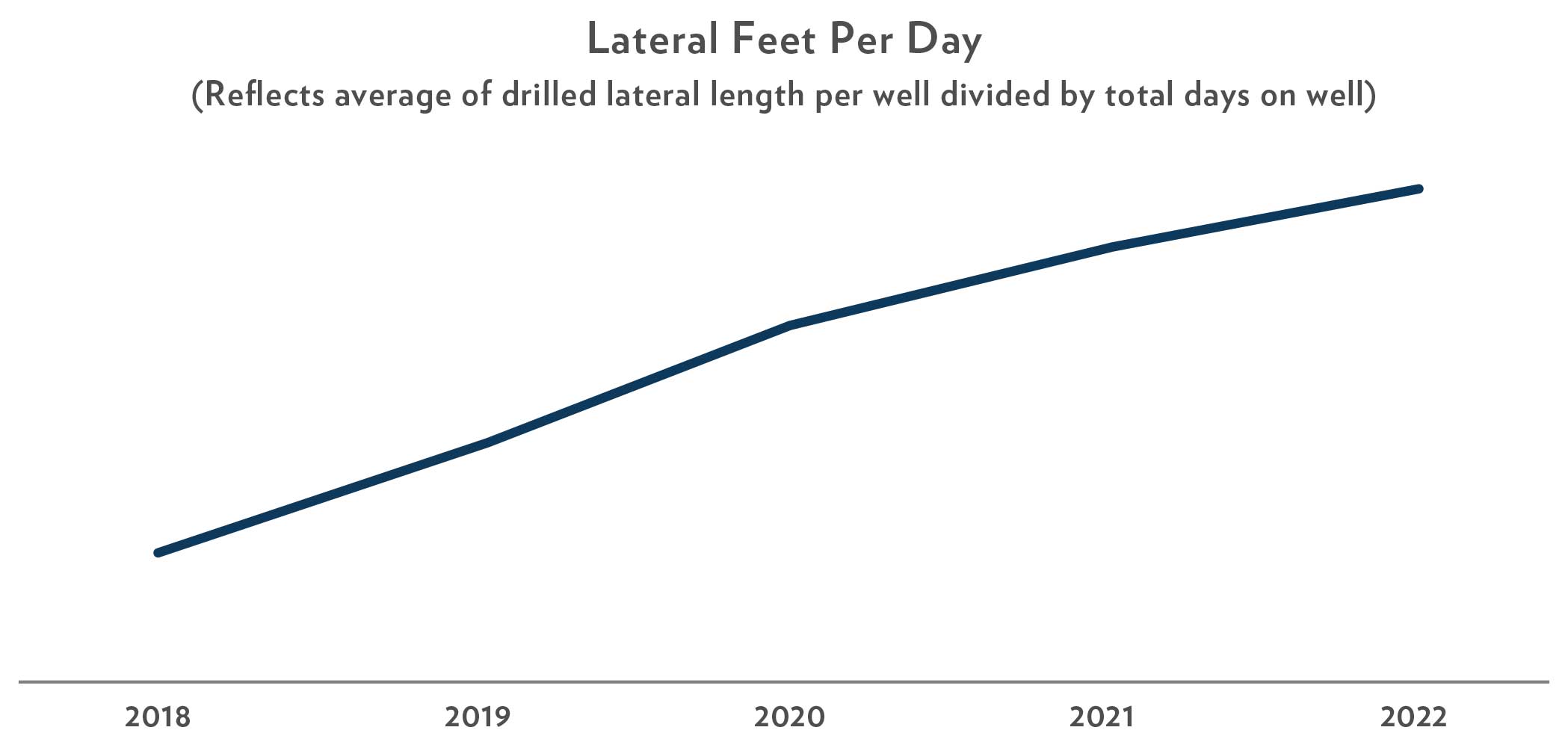

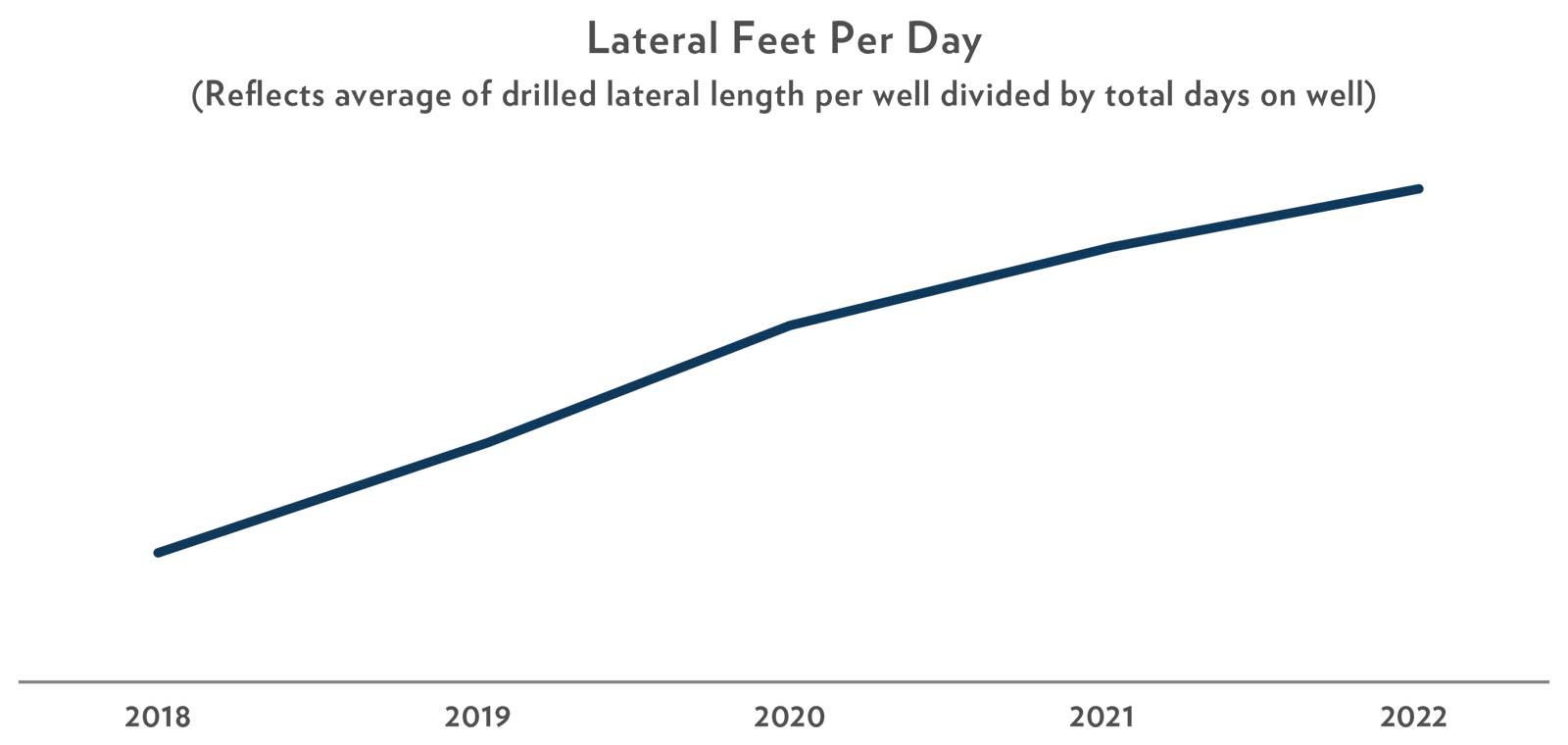

Over the last several years, the drilling team leveraged advancements in downhole technology and the use of our best-in-class remote operations center to make data-driven performance decisions. These technologies provided improvements in drilling efficiency, while also unlocking our ability to drill longer lateral lengths, as we saw our average lateral length drilled increase by 13% from 2021 to 2022. Additionally, the team has moved completely towards the use of a “spudder” rig to drill the surface-hole sections of our wells. This spudder rig is a much smaller drilling rig and thus generates lower emissions than our standard horizontal rig. This results in an overall reduced emissions profile for every well we drill. Lastly, through coordination and partnership with Pioneer’s drilling contractors, we identified and implemented further reductions in diesel generator emissions by utilizing digital technology and automation to improve rig engine efficiency. These efforts resulted in 4% fewer drilling-related emissions from 2021 to 2022, decreasing emissions per lateral foot by 4% since 2021 and increasing average feet per day by 13% over the same time period.

Our Completions team has also continued to deliver operational and emissions efficiencies by increasing average feet per day completed by 10% and decreasing emissions per lateral foot by 8% since 2021.

Driving Technology Advancement

Pioneer is an industry leader in advancing drilling and completion techniques and operational efficiencies. We invest annually in drilling and completions technology enhancements and participate in industry consortia. We have also implemented various digital field equipment enhancements to improve employee safety, lower capital and operating costs, refine field data capture, and reduce Pioneer’s overall environmental footprint.

Our drilling organization has successfully leveraged data science, statistics and engineering disciplines to automate various workflows that reduce operational variability and increase capital efficiency. By effectively merging predictive alerts, advanced models and 24/7 remote engineering support, we have digitized our workflows to make faster, more proactive and informed decisions.

Our Completions organization has partnered with software providers to design and build a customized, proprietary solution to livestream data from location, allowing engineers to monitor wells from any location and provide better support to operations. In addition to operational efficiency focus, we have deployed technologies to evaluate and modify completion designs that benefit capital efficiency. The utilization of technologies such as perforation imaging and fiber optics has allowed for data accessibility that has increased our knowledge of effective fracture placement and contributed to our design improvements.

In addition to efficiency gains, our Completions team is pursuing the advanced technology of e-fleets. Presently, we are on pace to continue this trend of improvement having onboarded two dual-fuel fleets, powered by both compressed natural gas and diesel, in late 2022. These dual-fuel fleets primarily utilize engines that significantly reduce NOx, CO and particulate matter (PM) emissions [Environmental Protection Agency (EPA) Tier IV standards] and are expected to displace up to 65% of the fleet’s diesel consumption with cleaner-burning natural gas. Additionally, we have plans to continue exploring and integrating new, emission-focused technologies into our program by transitioning our dedicated fleets to electric or dual-fuel powered pumps in 2023.

Reducing Completions Flaring – We have reduced flaring in our completions operations. Since 2018, the duration of circulating time (the phase of completions operations during which the well has the most potential to flare gas) has been shortened by more than 63%. As part of this practice, we have also transitioned 75% of drill-out flare utilization to on-pad-contained combustors. This increases our overall combustion efficiency and decreases our resultant emissions.

Electrifying Field Operations – Pioneer’s ability to achieve our net zero ambition is centered on being able to electrify our drilling, completions and production operations. Challenges exist for all operators in the Permian Basin as it pertains to electric transmission and generation, which may limit our ability to fully electrify our operations. Pioneer is actively partnering with our local utility provider to develop a long-term power delivery strategy that is essential to the success of field electrification. In addition, we have taken the following notable steps to begin implementing these progressive solutions:

- Compiled operational lessons learned from a 2021 multi-well. pad drilled using 100% high-line power in preparation for expanded high-line drilling

- Reviewed drilling rig power requirements and lessons learned from a 2021 pilot test of a hybrid rig using battery storage for peak load shaving

- Performed in depth, cross-disciplinary planning for increased utilization of high-line power for drilling operations as infrastructure allows

- Built on learnings from previous electric completions fleet trials by sourcing 40% electric fleets and gas-powered generators for dedicated utilization in 2023

- Leveraged high-line power to support auxiliary equipment for completions and post-completions activities on a trial basis

- Continued planning for opportunities to use high-line power for completions operations as infrastructure allows