Managing Produced Water

Produced water is the wastewater associated with oil and gas exploration, development and production activities. Pioneer utilizes two methods of managing produced water. One method involves injecting the water into underground reservoirs using water disposal wells. The other method involves treating the produced water at recycling facilities for reuse in completions operations. Pioneer owns and operates most of its produced water infrastructure, including gathering pipelines, water disposal wells and produced water recycling facilities. Pioneer also contracts with third-party operators and midstream counterparties to manage and prioritize water takeaway options in instances where it is not economically efficient for Pioneer to build out its own infrastructure. The prioritization of Pioneer’s water management philosophy is listed below.

Pioneer prioritizes produced water takeaway in the following tiers:

- Tier 1: Recycle for use in Pioneer’s completions activities

- Tier 2: Recycle for use in other operators’ completions activities

- Tier 3: Injection and takeaway

As Pioneer completions operations and water consumption have grown, produced water recycling has become more important.

Pioneer operates pipeline systems that allow us to manage water production according to the tiers above and handle future oil and gas development needs through both Pioneer-owned infrastructure and third parties. Pioneer complies with national and state regulations – including those imposed by the Texas Railroad Commission – on underground injection control regarding injection rate and pressure monitoring, pressure testing, and mechanical integrity testing. Pioneer also takes seismicity risks into account when deciding where to locate water disposal wells using the latest science and our own extensive data.

Produced Water Gathering Pipelines and Systems

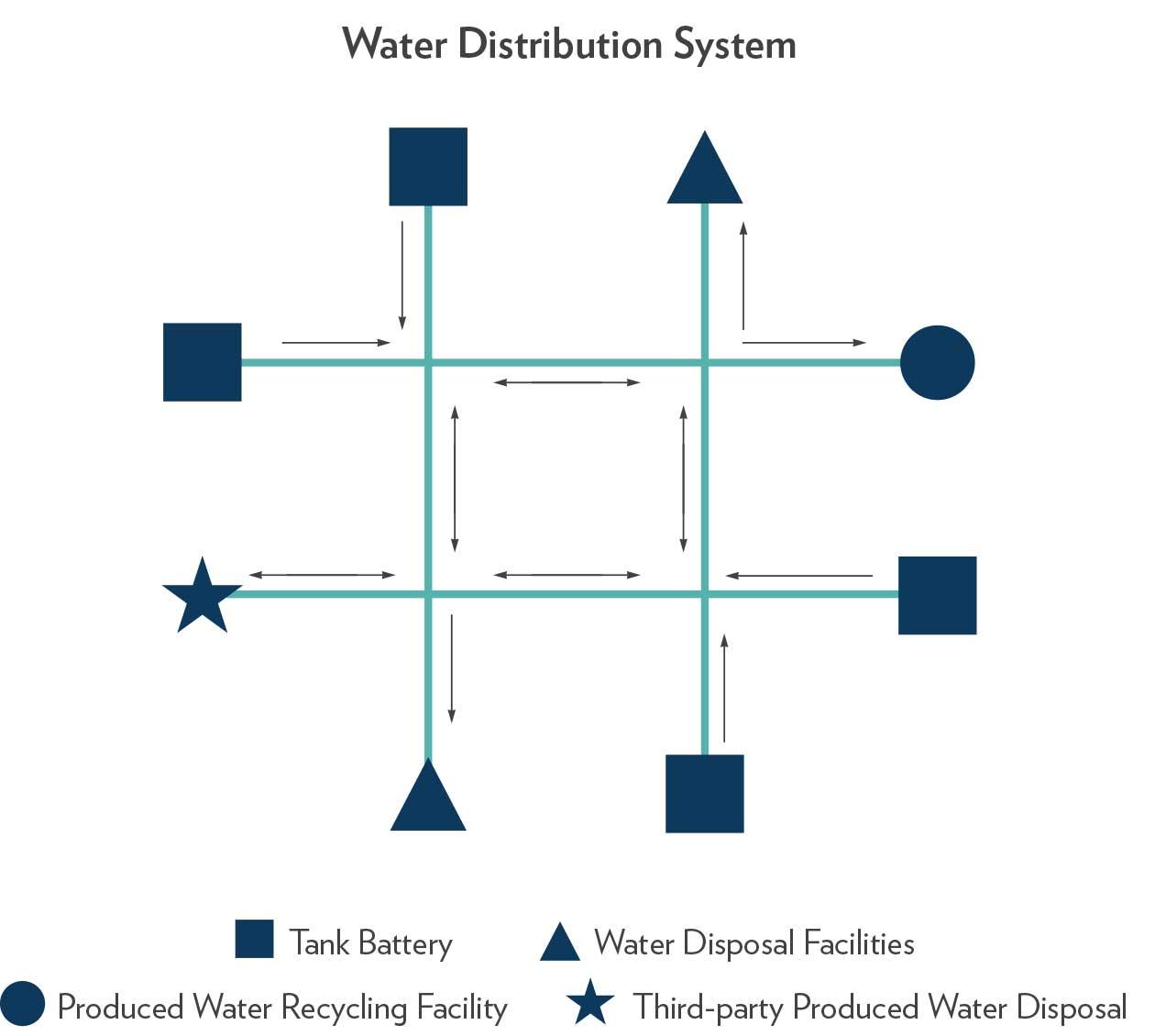

Pioneer gathers and separates well fluids, including produced water, at centralized facilities, often referred to as tank batteries. After separation, the produced water is transported by pipeline to both water disposal wells and produced water recycling facilities, eliminating the need to truck water. Pioneer connects our produced water gathering pipelines into networked systems where water is aggregated and distributed across multiple disposal wells and recycling facilities.

The ability to move produced water within networked systems is key to operating efficiently. Moving produced water in this manner provides operational redundancy, risk mitigation and cost efficiency. Connected systems aggregate water volumes into a larger baseload that provides economies of scale for treatment. Also, connecting to more facilities provides redundancy against downtime on any single facility and produced water takeaway optionality. Our networked systems also provide the flexibility to move water away from areas with significant development or where disposal options are constrained.

Produced Water Recycling

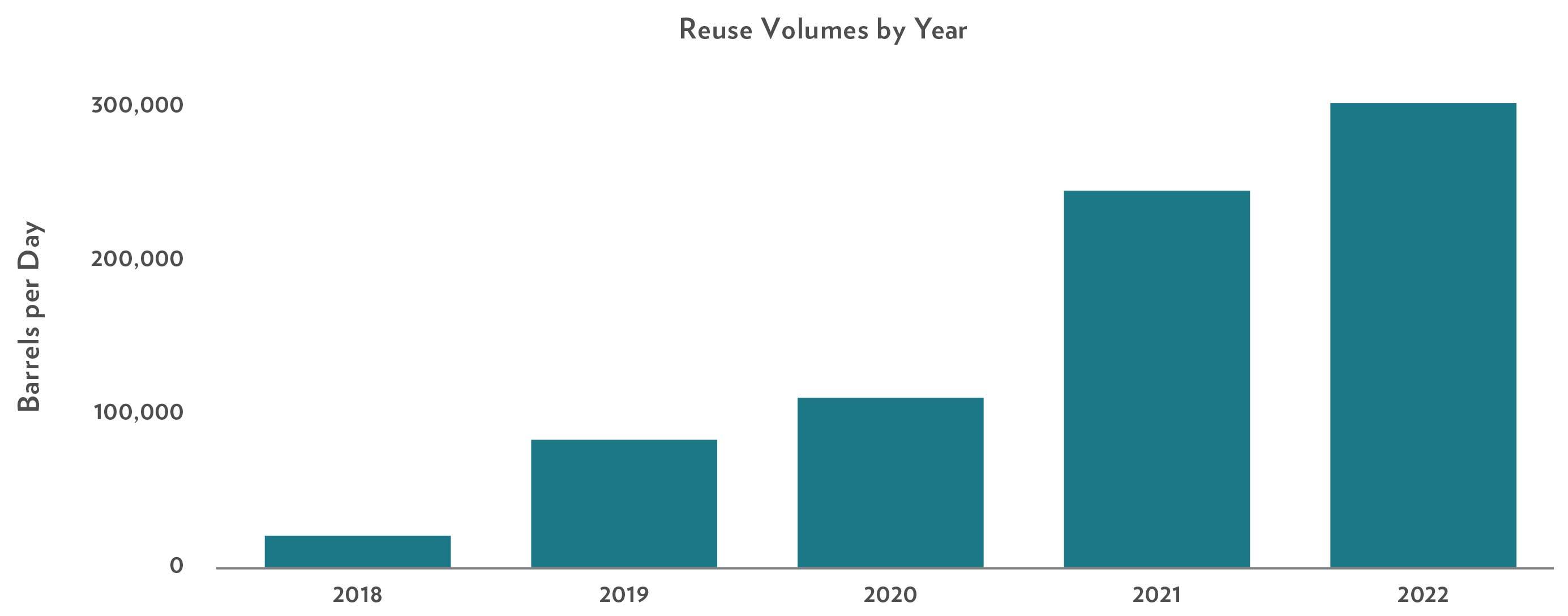

Pioneer utilizes proven and available technology to chemically and mechanically treat produced water to meet standards acceptable for storage and transportation. After the produced water is treated in recycling facilities, it is transferred into Pioneer’s mainline supply system where it is stored and transported to completions operations. Recycling simultaneously eliminates the need to source freshwater and inject produced water. Pioneer produces more water than we consume in our operations and therefore cannot rely on recycling alone to manage produced water. Still, Pioneer has increased our reuse of recycled produced water more than tenfold since 2018.

Strategic Flexibility and Future Evaluations

The flexibility provided by Pioneer’s produced water infrastructure, combined with our substantial mainline supply infrastructure, allows us to access significant volumes of recycled produced water for hydraulic fracturing. These two systems operate independently but are connected at produced water recycling facilities. Our mainline 45supply infrastructure allows us to deliver recycled water to completions operations across our acreage throughout the Permian Basin.

Pioneer is evaluating available desalination technologies and looking for opportunities to progress the potential beneficial reuse and surface discharge of produced water. Pioneer defines beneficial reuse of produced water as the act of using produced water outside of the oil and gas industry, which differentiates it from our current reuse program. This includes creating freshwater for surface discharge, potential agricultural uses, other industrial uses, and any other use that benefits the environment and protects freshwater. Pioneer is pursuing these beneficial reuse efforts through several channels, including engagement with regulatory agencies to understand permitting requirements, technology vendors to understand economic and engineering requirements, consortia to help engage policy makers, and trade groups to collaborate with others.